- Trapezoidal Machine

- Corrugated Machine

- Glazed Tile Machine

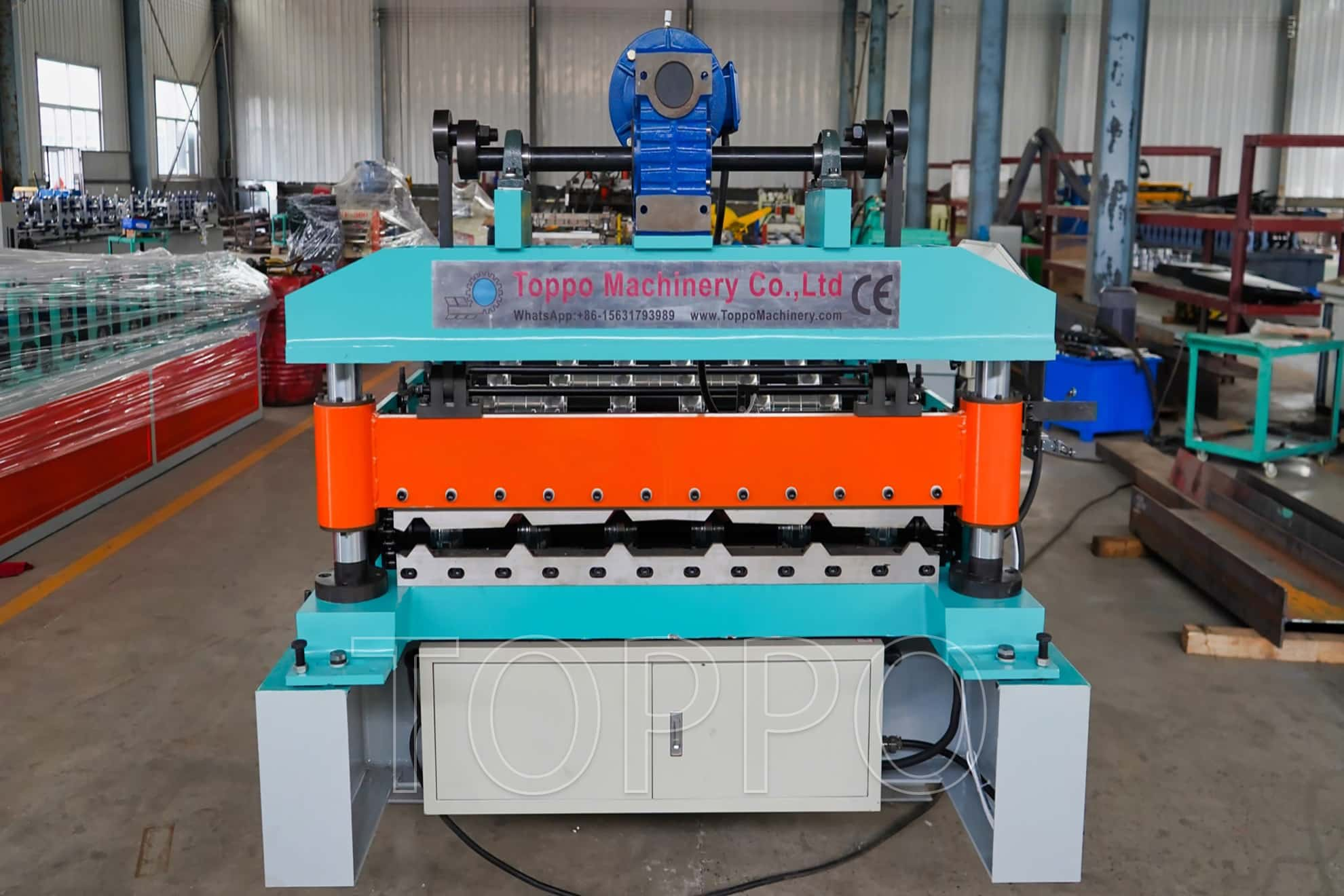

- Double Layer Machine

- CZU Purlin Machine

- Ridge Cap Machine

- Floor Decking Machine

- Rolling Door Machine

- Fence Machine

- Embossing Machine

- Standing Seam Machine

- Cut To Length And Slitting Line

- Guard Rail Machine

- Decoiler And Stacker

- Stud And Track Machine

- Gutter And DownPipe

- Curving Machine

- Cladding Panel Machine

- Corollary Equipment

Trends Shaping the Roofing Sheet Industry in Latin America (2025 Edition)

As Latin America’s construction and manufacturing sectors rapidly evolve, the roofing sheet industry is seeing significant changes driven by innovation, sustainability, and regional demand. This article explores the most influential trends in 2025, with practical steps for implementation, common mistakes to avoid, and real-world case studies—focused on leveraging advanced equipment like the Automatic Tr5 Tr6 metal trapezoidal roof panel roll forming machine.

1. Digitalization and Smart Manufacturing

Latin American producers are increasingly adopting digital tools to streamline operations. The integration of automated systems such as the Automatic Tr5 Tr6 metal trapezoidal roof panel roll forming machine allows for real-time monitoring and data-driven quality control.

Steps to Implement:

Invest in machines with digital controls and IoT connectivity.

Train operators to analyze real-time data and adjust settings accordingly.

Set up scheduled software updates and calibrations.

Common Pitfalls:

Ignoring manufacturer-recommended software updates, leading to compatibility issues.

Failing to train staff, resulting in underutilization of digital features.

Case: A Brazilian manufacturer reduced production errors by 35% after upgrading to a fully automated roof panel making machine and providing monthly data training for staff.

2. Focus on Energy Efficiency and Sustainability

With rising energy costs and environmental regulations, manufacturers prioritize energy-efficient solutions. The latest trapezoidal roll forming machine models are equipped with variable frequency drives and energy-saving modes.

Steps to Implement:

Replace outdated equipment with energy-efficient models.

Monitor energy usage via integrated dashboards.

Use recyclable materials in panel production.

Common Pitfalls:

Skipping regular maintenance, which increases energy waste.

Overlooking the use of certified, sustainable materials.

Case: A Chilean company decreased its energy consumption by 22% and qualified for government green incentives after investing in a new Automatic Tr5 Tr6 machine.

3. Diversification of Product Range

To remain competitive, Latin American factories are diversifying product offerings using flexible roof panel making machines. This enables the production of various profiles and customized orders without lengthy changeover times.

Steps to Implement:

Choose machines with quick-change die systems.

Train staff on rapid profile switching.

Maintain detailed logs of customer requirements and profile settings.

Common Pitfalls:

Not documenting settings, causing errors during changeovers.

Relying on outdated manual adjustment methods.

Case: A Mexican sheet producer boosted its customer base by 40% by offering custom panel profiles with its new trapezoidal roll forming machine.

4. Localized Production and Supply Chain Resilience

Latin America’s supply chain disruptions have motivated many businesses to establish localized production with advanced machines, reducing lead times and risk.

Steps to Implement:

Set up small, flexible production sites with Automatic Tr5 Tr6 machines.

Develop local supplier relationships for steel coils.

Build redundancy into logistics planning.

Common Pitfalls:

Neglecting local supplier vetting, resulting in quality issues.

Not planning for spare parts availability.

Case: An Argentinian company cut project delivery time in half by launching local production with its own roll forming line.

5. Operator Training and Workforce Development

Technology is only as good as its users. Regular training on the latest roof panel making machine and trapezoidal roll forming machine technology is crucial.

Steps to Implement:

Schedule quarterly technical workshops.

Implement a mentorship program for new hires.

Create a troubleshooting guide specific to the Automatic Tr5 Tr6 machine.

Common Pitfalls:

Infrequent or outdated training sessions.

Lack of practical, hands-on instruction.

Case: A Peruvian manufacturer saw a 20% reduction in unplanned downtime after starting a monthly training initiative.

SEO Keywords(40组)

Automatic Tr5 Tr6 metal trapezoidal roof panel roll forming machine, roof panel making machine, trapezoidal roll forming machine, digital manufacturing, IoT roofing equipment, Latin America roofing trends, energy-efficient roll forming, variable frequency drives, green building incentives, local production, supply chain resilience, profile customization, quick-change die system, staff digital training, government incentives roofing, recyclable panel materials, production dashboard, error reduction, data-driven quality, energy monitoring, sustainable roofing sheet, downtime reduction, customer profile logging, flexible sheet forming, logistics planning, rapid changeover, training workshop, Argentinian manufacturer, Mexican sheet producer, Brazilian digitalization, Peruvian workforce, Chilean energy efficiency, certified sustainable materials, profile switching, local supplier relationships, spare part planning, technical mentorship, troubleshooting guide, hands-on machine training

Tags(SEO关键词)

Automatic Tr5 Tr6 metal trapezoidal roof panel roll forming machine, roof panel making machine, trapezoidal roll forming machine, Latin America roofing trends, digital manufacturing, energy-efficient roll forming

READ MORE:

Industrial Builders in Latin America: Unlocking Efficiency with the Latest Roll Forming Innovations

How Architects and Designers in Latin America Can Lead Roofing Innovation in 2025

Latin American Distributors: Strategies for Succeeding in the Roofing Sheet Supply Chain (2025)

How Roofing Contractors in Latin America Can Stay Ahead with Advanced Roll Forming Technology