- Trapezoidal Machine

- Corrugated Machine

- Glazed Tile Machine

- Double Layer Machine

- CZU Purlin Machine

- Ridge Cap Machine

- Floor Decking Machine

- Rolling Door Machine

- Fence Machine

- Embossing Machine

- Standing Seam Machine

- Cut To Length And Slitting Line

- Guard Rail Machine

- Decoiler And Stacker

- Stud And Track Machine

- Gutter And DownPipe

- Curving Machine

- Cladding Panel Machine

- Corollary Equipment

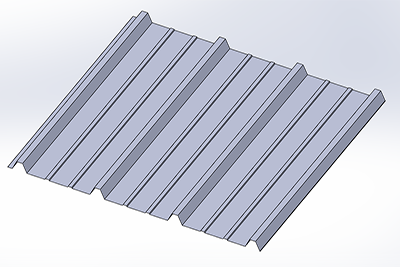

- Trapezoidal Machine

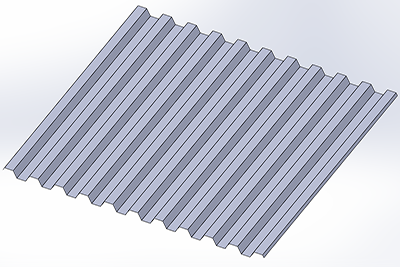

- Corrugated Machine

- Glazed Tile Machine

- Double Layer Machine

- CZU Purlin Machine

- Ridge Cap Machine

- Floor Decking Machine

- Rolling Shutter Door Machine

- Palisade Fence Machine

- Embossing Machine

- Standing Seam Machine

- Cut To Length And Slitting Line

- Guard Rail Machine

- Decoiler And Stacker

- Stud And Track Machine

- Gutter And DownPipe

- Curving Machine

- Cladding Panel Machine

- Corollary Equipment

- Other

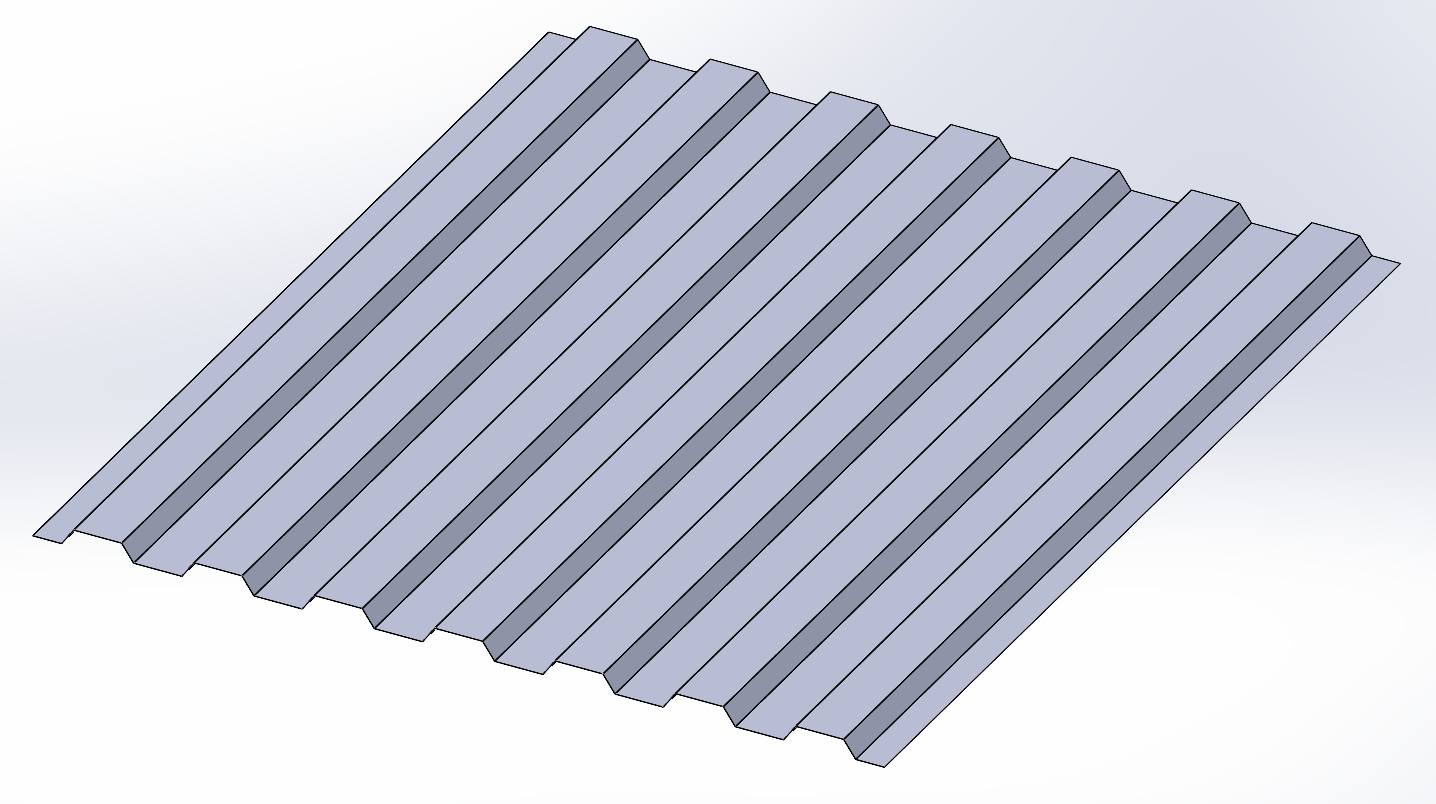

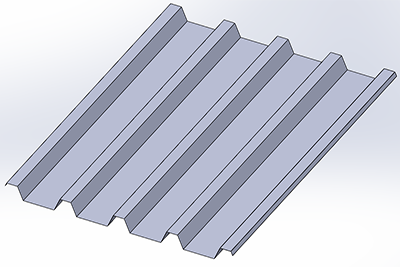

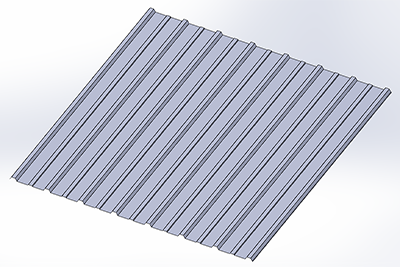

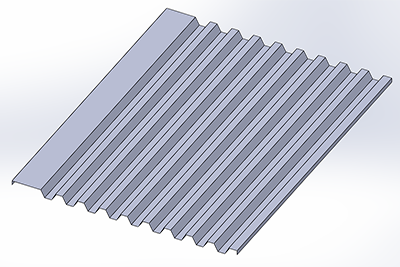

Trapezoidal Roof Panel Roll Forming Machine - Technical Configuration

-

Brand: Toppo Machinery Co., Ltd

-

Model: Compact Trapezoidal Panel Machine

-

Function: Metal Roofing Panel Forming

-

Material: Galvanized Steel, PPGI, Aluminum

-

Material Thickness: 0.3–0.8 mm

-

Panel Effective Width: 760–1100 mm

-

Feeding Coil Width: 1000–1250 mm

-

Forming Steps: 16–22 Stations

-

Roller Material: GCr15 with Chrome Coating

-

Shaft Diameter: 70 mm

-

Drive System: Chain or Gear Driven

-

Main Motor Power: 5.5 kW

-

Hydraulic Power: 4 kW

-

Cutting Mode: Hydraulic Post-Cutting

-

Blade Material: Cr12Mov (Heat Treatment)

-

PLC Control: Siemens or Delta

-

Touch Screen: User-Friendly HMI

-

Working Speed: 10–15 m/min

-

Power Supply: 380V, 50Hz, 3Phase

-

Machine Frame: 350H Steel Welded

-

Color Scheme: Blue + Yellow (Customizable)

-

Machine Dimension: 8800*1400*1400 mm

-

Weight: About 5 Tons

-

Noise Level: ≤70 dB

-

Accuracy: ±1 mm

-

Cooling Type: Air Cooling

-

Lubrication: Automatic / Manual Oil System

-

Safety Devices: Emergency Stop Button

-

Packaging: Film Wrapped and Steel Wire Fixed

-

Warranty: 1 Year

-

Lead Time: 25–30 Days

-

MOQ: 1 Set

-

OEM/ODM: Support Available

-

Custom Design: Free CAD Profile Service

-

After-sales Service: Engineers Overseas, Video Support

-

Ease of Operation: Simplified Control System

-

Usage Scenarios: Industrial Warehouses, Steel Roof Projects

-

Performance: Stable, Continuous Production for Large-Scale Use

This machine offers excellent forming accuracy and long-lasting performance. It's widely chosen by small to medium steel structure manufacturers for its compact footprint and superior automation level.

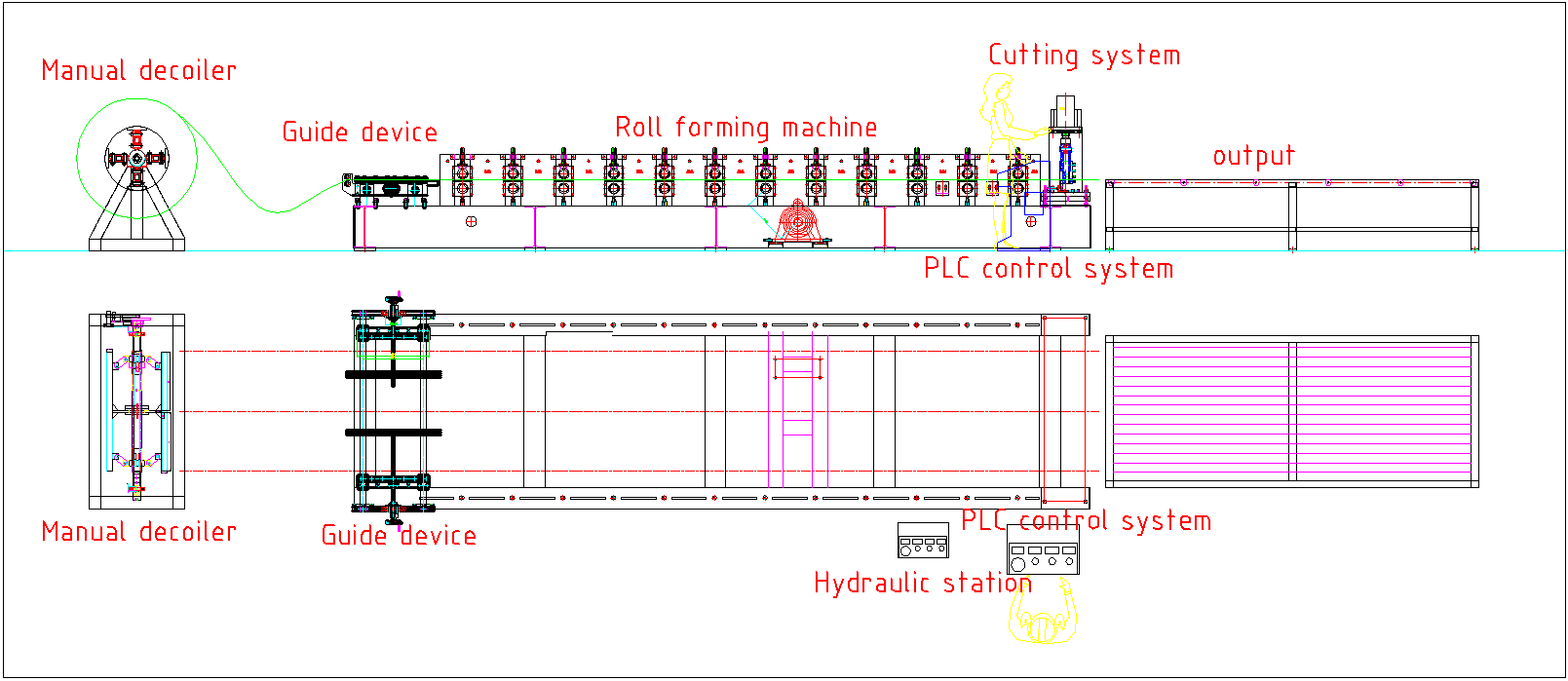

Drawing(Partial display)

Layout

Application

End Product

Roofing panel roll forming machine Description

This Trapezoidal Roof Panel Roll Forming Machine is a fully automatic equipment specially designed for manufacturing steel trapezoidal roofing sheets. With high forming speed, precise cutting, and intelligent control, it offers an ideal solution for construction material producers. The equipment is easy to operate, durable, and provides excellent production efficiency, suitable for both small workshops and large industrial manufacturing lines

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-